Craftsman 1940's metal lathe.

Moderator: RLG MGMT Team

-

BlackHawk*K

- Posts: 1051

- Joined: 12 May 2001, 17:00

- Location: Oklahoma

Craftsman 1940's metal lathe.

i have a Craftsman 618 metal lathe. i have had it for a few years now. when i first got it, i did a quick clean up job and painted it but that was it.

Recently i decided to do a complete tear down, clean up and rebuild. on a metal lathe, especially this one, its important. the gears are composed of ZEMACK, a kind of aluminum alloy. after time, metal shavings can embed themselves into the gears. and besides its always good to go back and check tolerances and wear.

i didnt take any before pictures. i didnt even think about photos until after i got the tail stock, carriage and cross slide and the bed cleaned and painted.

but here are some pictures from that point on if anyone is interested.

http://smg.photobucket.com/user/VoidHaw ... sman%20618

( quick note, this should allow you to see the whole album. if not leave a comment below and i will figure out where i messed up.)

i will take more pics as i get the counter pulley, motor and stuff installed and going.

thanks for looking!

Recently i decided to do a complete tear down, clean up and rebuild. on a metal lathe, especially this one, its important. the gears are composed of ZEMACK, a kind of aluminum alloy. after time, metal shavings can embed themselves into the gears. and besides its always good to go back and check tolerances and wear.

i didnt take any before pictures. i didnt even think about photos until after i got the tail stock, carriage and cross slide and the bed cleaned and painted.

but here are some pictures from that point on if anyone is interested.

http://smg.photobucket.com/user/VoidHaw ... sman%20618

( quick note, this should allow you to see the whole album. if not leave a comment below and i will figure out where i messed up.)

i will take more pics as i get the counter pulley, motor and stuff installed and going.

thanks for looking!

-

Bronurstomp

- Posts: 319

- Joined: 30 Oct 2008, 05:21

- Location: New England USA

Re: Craftsman 1940's metal lathe.

Dude, I wish we lived closer together. I could help you with that. Looks like you have a lot to put back together lol... and when your done, you'd love using it to help with my new battlebot.

http://vid295.photobucket.com/albums/mm ... sz5x7i.mp4

I need new axles made. I'll have to try the bandsaw. I picked up a bimetal blade and try it later.

http://vid295.photobucket.com/albums/mm ... sz5x7i.mp4

I need new axles made. I'll have to try the bandsaw. I picked up a bimetal blade and try it later.

-

BlackHawk*K

- Posts: 1051

- Joined: 12 May 2001, 17:00

- Location: Oklahoma

Re: Craftsman 1940's metal lathe.

nice man!

lol, is that a Deans connector on your bot? u used to use those all the time in my R/C stuff.

yea man if i lived real close between you and i, i bet there wouldnt be much we couldnt build hehe.

i have the Lathe together now, its just i need to find a good way to mount the Motor and the Counter pulley. ( i actually need a non Blackhawked Frankenstein one...) Plus there is all the random tooling i may or may not need.

i had to put the Lathe project on hold. actually a majority of my projects. it looks like the ex-wife decided to go ahead and screw me over, despite the fact i had the kids with me until last November, at that point, i decided to let them move in with their mother, because they wanted to go to another school located where she is. i should of known she would get on cash assistance threw the state. and since its in the state, im pretty much screwed. im still in the process fighting it. i doubt i will get it to go away, but im trying to minimize the damage, since the state's proposal is full of non-factual crap. will see how it goes.

if i get to the point i can get back to my projects, ( or run away to texas or oklahoma. ) i will let you know lol.

Meanwhile, i am still pretty involved in star citizen. mainly been kicking ass racing. i am in the top 25 on all the leader boards and that is no small achievement. i have been watching Star citizen streams lately. sometimes they do raffles for stuff. at this point ive won about $60 in prizes. on of those was the Merlin snub nose ship lol. if i keep it up, i should be able to melt this stuff down and buy another ship for free meanwhile, my hanger is getting cluttered with hanger flair hehe.

meanwhile, my hanger is getting cluttered with hanger flair hehe.

work is still pretty slow right now. hopefully that will pick up again soon as well.

lol, is that a Deans connector on your bot? u used to use those all the time in my R/C stuff.

yea man if i lived real close between you and i, i bet there wouldnt be much we couldnt build hehe.

i have the Lathe together now, its just i need to find a good way to mount the Motor and the Counter pulley. ( i actually need a non Blackhawked Frankenstein one...) Plus there is all the random tooling i may or may not need.

i had to put the Lathe project on hold. actually a majority of my projects. it looks like the ex-wife decided to go ahead and screw me over, despite the fact i had the kids with me until last November, at that point, i decided to let them move in with their mother, because they wanted to go to another school located where she is. i should of known she would get on cash assistance threw the state. and since its in the state, im pretty much screwed. im still in the process fighting it. i doubt i will get it to go away, but im trying to minimize the damage, since the state's proposal is full of non-factual crap. will see how it goes.

if i get to the point i can get back to my projects, ( or run away to texas or oklahoma. ) i will let you know lol.

Meanwhile, i am still pretty involved in star citizen. mainly been kicking ass racing. i am in the top 25 on all the leader boards and that is no small achievement. i have been watching Star citizen streams lately. sometimes they do raffles for stuff. at this point ive won about $60 in prizes. on of those was the Merlin snub nose ship lol. if i keep it up, i should be able to melt this stuff down and buy another ship for free

work is still pretty slow right now. hopefully that will pick up again soon as well.

Re: Craftsman 1940's metal lathe.

deans connectors are better. if i recall, less resistance? let's see if Bron our EE will enlighten us.

Helmut

-

BlackHawk*K

- Posts: 1051

- Joined: 12 May 2001, 17:00

- Location: Oklahoma

Re: Craftsman 1940's metal lathe.

they actually have a few different types of Deans connectors. i used the 4 prong type for my R/C stuff. in my case i needed it because i used to race heavy modified trucks on race tracks, back when that used to be a thing LOL. i have a little plaque with all these cute little awards

-

Bronurstomp

- Posts: 319

- Joined: 30 Oct 2008, 05:21

- Location: New England USA

Re: Craftsman 1940's metal lathe.

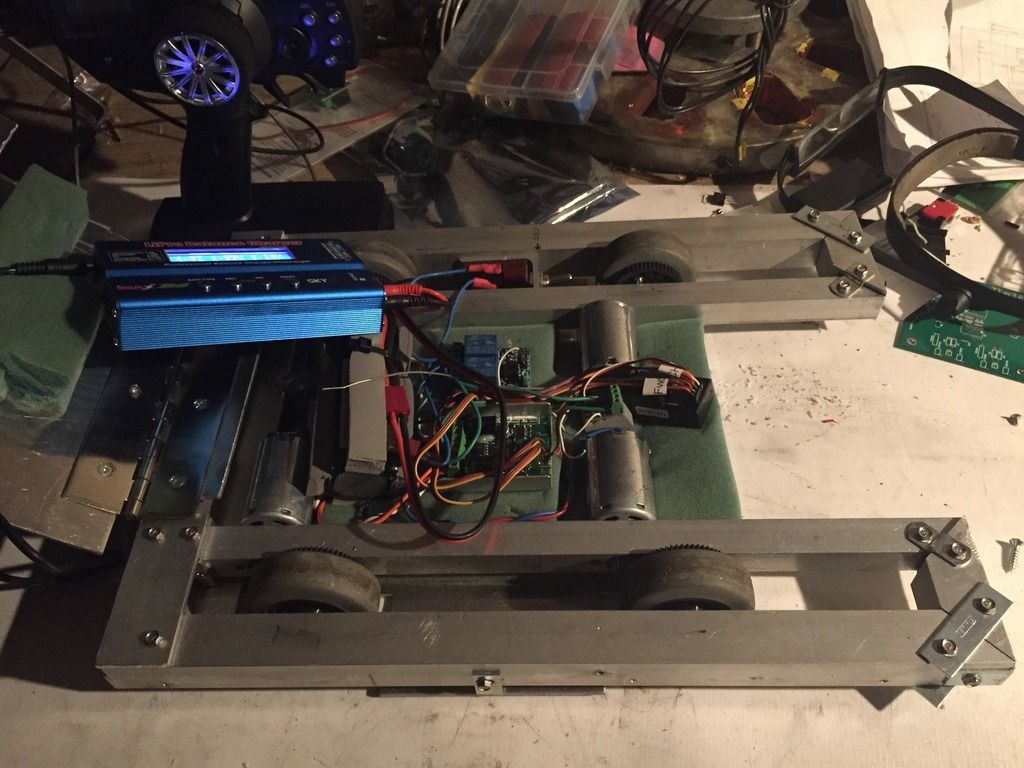

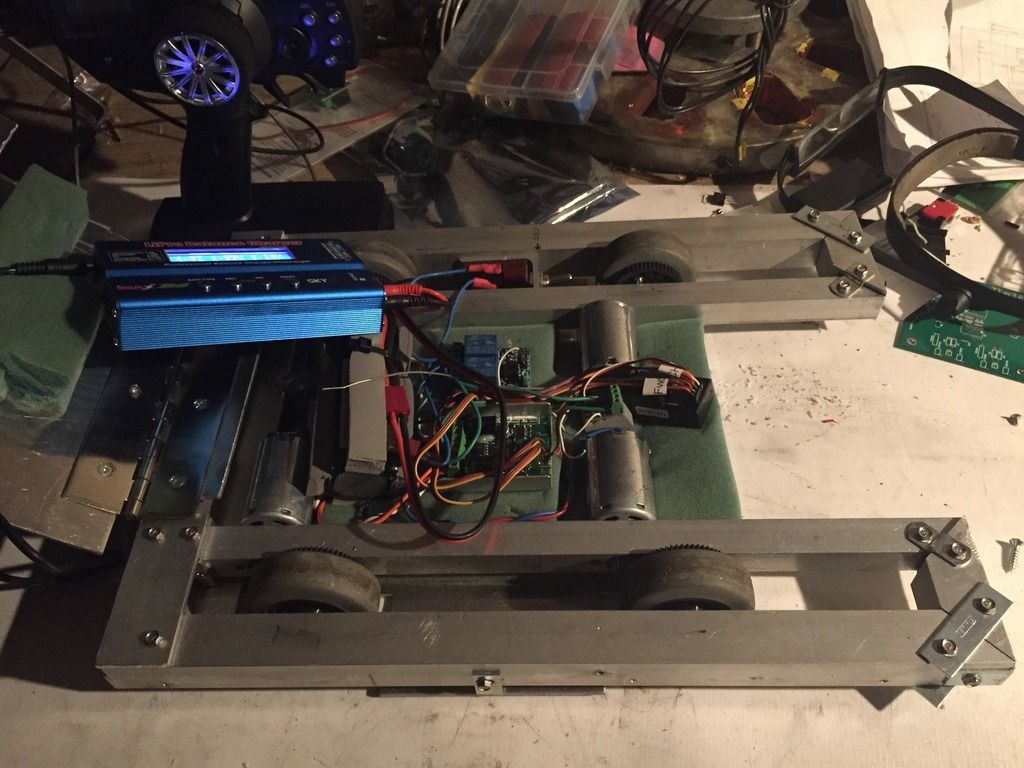

Yep definitely Deans connectors. Reliable, keyed, redily available, and spring loaded so they don't vibrate apart. I wrapped my battery in nice thick window insulation foam tape, you know that gray stuff about 1/2 thick? That and a 1 inch layer of loose cell foam on top and bottom cover plates sandwiches that and the electronics. No shakey loose anything.

I got to drive it around tonight on his shop floor, upside down, and it really drives nice. I'll need plenty of practice, but we're registered for a December 5th competition.

Still need to fabricate some spares...

No new pics up yet. It's late, just got back from working on Bron2Stomp with my son at his shop. His task is the weapon system.

I got all the electronics working. Finally got the top cover and hinge fabricated and installed so I could run around upside down while I work on the bottom plate.

I've added a bunch of off the shelve stainless parts to bolt things together and shore up the corners in case we don't get the weapon running great. The spin speed is enough to do some good damage just running into the other bots, and nailing them with the SS bits.

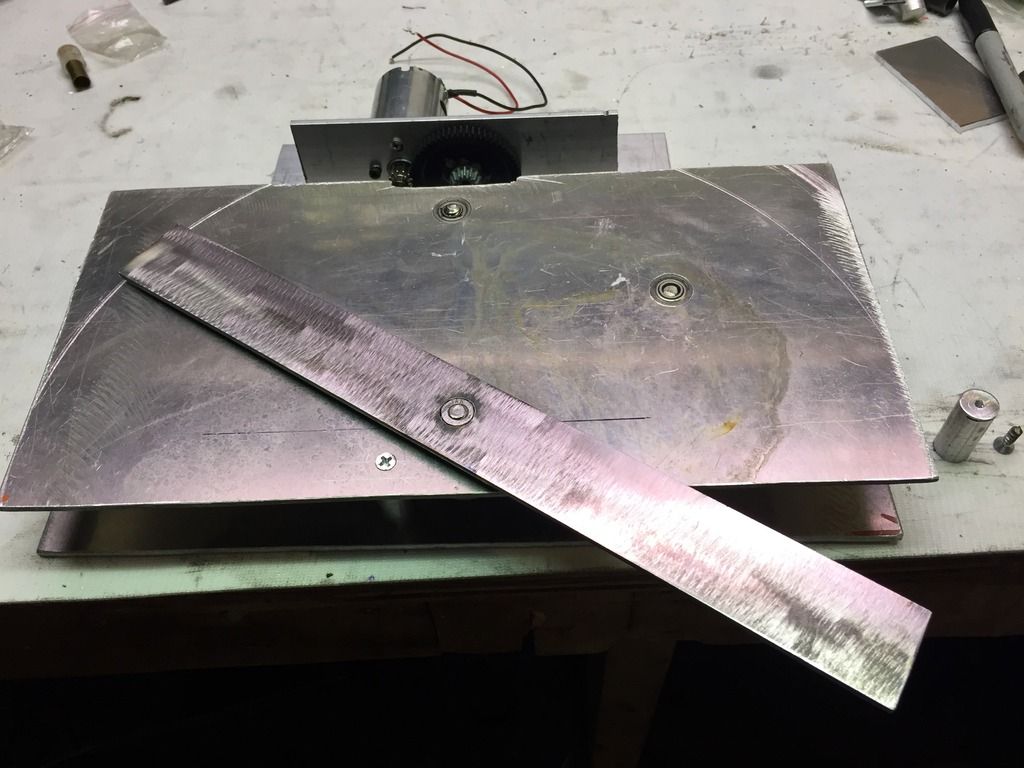

The main weapon is a spinner, just like the boigger one. We are putting a bevel gear set in like a single sided differential to spin the weapon blade. Decided to add a belt drive so it can slip on impact, instead of crumbling the gear set on impact. SO of course we need a tensioner pully... whew. We got most of it figured out. He'll have to finish his part while I work on the bottom cover plate.

MWO is still semi-brainless good fun now and then, as well as some planetside2 action. I don't really have energy to learn and relearn SC as it evolves. I'll bide my time and get serious when it gets released.

Counting on you BlackHawk to keep us in the loop about important stuff... and grats on all the Hangar bling!

Bron

I got to drive it around tonight on his shop floor, upside down, and it really drives nice. I'll need plenty of practice, but we're registered for a December 5th competition.

Still need to fabricate some spares...

No new pics up yet. It's late, just got back from working on Bron2Stomp with my son at his shop. His task is the weapon system.

I got all the electronics working. Finally got the top cover and hinge fabricated and installed so I could run around upside down while I work on the bottom plate.

I've added a bunch of off the shelve stainless parts to bolt things together and shore up the corners in case we don't get the weapon running great. The spin speed is enough to do some good damage just running into the other bots, and nailing them with the SS bits.

The main weapon is a spinner, just like the boigger one. We are putting a bevel gear set in like a single sided differential to spin the weapon blade. Decided to add a belt drive so it can slip on impact, instead of crumbling the gear set on impact. SO of course we need a tensioner pully... whew. We got most of it figured out. He'll have to finish his part while I work on the bottom cover plate.

MWO is still semi-brainless good fun now and then, as well as some planetside2 action. I don't really have energy to learn and relearn SC as it evolves. I'll bide my time and get serious when it gets released.

Counting on you BlackHawk to keep us in the loop about important stuff... and grats on all the Hangar bling!

Bron

-

BlackHawk*K

- Posts: 1051

- Joined: 12 May 2001, 17:00

- Location: Oklahoma

Re: Craftsman 1940's metal lathe.

yea for ease of use the V-Belt way is a good way to go. the metal lathes use this a lot to allow slippage if you happen to jam up the works while working. a really good way to protect gears at least as far as R/C cars went, was to use a gear with ball bearings embedded in it sandwiched between 2 spring loaded plates. the idea is you can adjust the tension by a nut that would squeeze the spring tighter if needed. but im not sure how easy it would be to make that system. the project sounds like a lot of fun man. i wish i lived closer

as to star citizen, yea they have added a LOT of content here recently. we now have a large map thats about the size of a single system. it has a set of mini missions, a first person shooter area. and a refuel and repair base. its really cool so far, but it hasnt been introduced to the live servers yet. we are still working out bugs. i got lucky this round and got selected for the second batch of testers to go in and break the game lol. the cool thing is they have changed the flight models around some, we now have 4 different flight modes. precision mode, space combat mode, cruise mode and quantum travel. they have also introduced multiplayer ships. so far its just the Super hornet, the Cutlass black, the Constellation and the retaliator. hopefully we will keep breaking things so they can get em fixed up so we can get this thing out on the live servers, then we can really dive into what it will be like to use the multi crew function in the game.

anyways, i hope all you guys have a great turkey day!

<S>!

as to star citizen, yea they have added a LOT of content here recently. we now have a large map thats about the size of a single system. it has a set of mini missions, a first person shooter area. and a refuel and repair base. its really cool so far, but it hasnt been introduced to the live servers yet. we are still working out bugs. i got lucky this round and got selected for the second batch of testers to go in and break the game lol. the cool thing is they have changed the flight models around some, we now have 4 different flight modes. precision mode, space combat mode, cruise mode and quantum travel. they have also introduced multiplayer ships. so far its just the Super hornet, the Cutlass black, the Constellation and the retaliator. hopefully we will keep breaking things so they can get em fixed up so we can get this thing out on the live servers, then we can really dive into what it will be like to use the multi crew function in the game.

anyways, i hope all you guys have a great turkey day!

<S>!

-

Bronurstomp

- Posts: 319

- Joined: 30 Oct 2008, 05:21

- Location: New England USA

Re: Craftsman 1940's metal lathe.

I'll have to have someone video it while I test drive it. But it seems to be running as expected, which is great. I still have a lot of work to do on the weapon assembly, but the design is mostly done.

Cheers!

I hope ya'll had a very pleasant Thanksgiving. Mine was the usual, big loud family get together, lotsa great food, some TV football, and card games.

http://vid295.photobucket.com/albums/mm ... cyh1so.mp4

Cheers!

I hope ya'll had a very pleasant Thanksgiving. Mine was the usual, big loud family get together, lotsa great food, some TV football, and card games.

http://vid295.photobucket.com/albums/mm ... cyh1so.mp4

Re: Craftsman 1940's metal lathe.

looks pretty good. nice and low to the ground, hopefully difficult to flip. wondering, why gear instead of direct drive? do you get more torque with your gears?

Helmut

-

Bronurstomp

- Posts: 319

- Joined: 30 Oct 2008, 05:21

- Location: New England USA

Re: Craftsman 1940's metal lathe.

Did you notice the link to the video? It's already pretty damn fast!

I used surplus motors, and they are almost 6,000 RPM, so the speed would have been insane without the 3-1 gear reduction. Also, it made interfacing to the wheels a lot less painful. Just screw a $2 gear onto the wheel, press one onto the motor shaft, and line everything up, 4 times lol...

I don't have a lathe like Chris does, to turn my own axles, and yes you are right about the torque, the added 3X torque is nice

It's actually ok if it gets flipped, I designed it so the profile is the same right side up or upside down. It has reversible throttle and steering that can be done quickly with the radio, so if it does get flipped, I can still drive it.

Working feverishly on the weapon system.

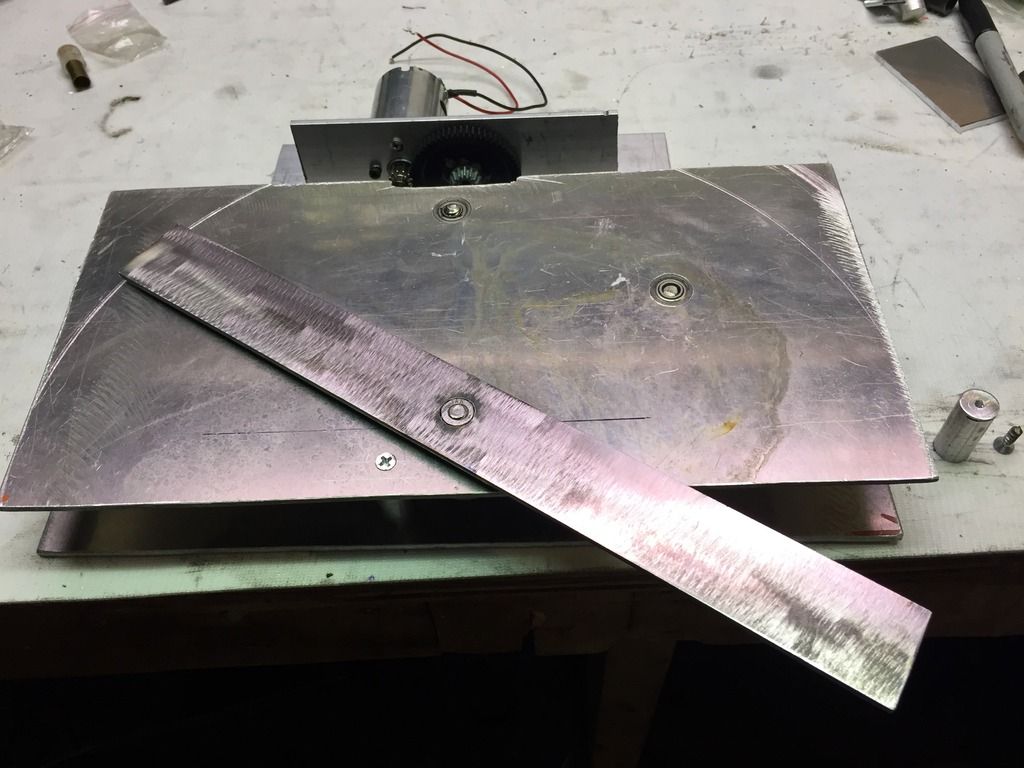

An active weapon is a requirement, so... We have an 11" tool steel spinner blade being driven with the same type motor, but with a 15-1 gear reduction (Weapon speed is limited to 400RPM), and a belt drive. My son welded a 1/4-20 nut onto the center of the blade, and we are using a 1/4-20 bolt as the shaft, coupled to a timing drive pulley. But instead of a timeing belt, we're using a stretched smooth belt so it can slip on impact.

Competition is on the 5th, so pant pant pant... trying to get it done! So may screws! So little loctite!

Bron

I used surplus motors, and they are almost 6,000 RPM, so the speed would have been insane without the 3-1 gear reduction. Also, it made interfacing to the wheels a lot less painful. Just screw a $2 gear onto the wheel, press one onto the motor shaft, and line everything up, 4 times lol...

I don't have a lathe like Chris does, to turn my own axles, and yes you are right about the torque, the added 3X torque is nice

It's actually ok if it gets flipped, I designed it so the profile is the same right side up or upside down. It has reversible throttle and steering that can be done quickly with the radio, so if it does get flipped, I can still drive it.

Working feverishly on the weapon system.

An active weapon is a requirement, so... We have an 11" tool steel spinner blade being driven with the same type motor, but with a 15-1 gear reduction (Weapon speed is limited to 400RPM), and a belt drive. My son welded a 1/4-20 nut onto the center of the blade, and we are using a 1/4-20 bolt as the shaft, coupled to a timing drive pulley. But instead of a timeing belt, we're using a stretched smooth belt so it can slip on impact.

Competition is on the 5th, so pant pant pant... trying to get it done! So may screws! So little loctite!

Bron

Re: Craftsman 1940's metal lathe.

so is the weapon sticking out the front? so that if it does get flipped it does not matter to the weapon except for a direction reversal on the blade spin?

Helmut

-

BlackHawk*K

- Posts: 1051

- Joined: 12 May 2001, 17:00

- Location: Oklahoma

Re: Craftsman 1940's metal lathe.

Bron, i didnt notice the video before. but that little bugger is fast! lol.

the project looks like a lot of fun. if i get lucky maybe one day i can reach a point i can get into something like this

the project looks like a lot of fun. if i get lucky maybe one day i can reach a point i can get into something like this

-

Bronurstomp

- Posts: 319

- Joined: 30 Oct 2008, 05:21

- Location: New England USA

-

Bronurstomp

- Posts: 319

- Joined: 30 Oct 2008, 05:21

- Location: New England USA

Re: Craftsman 1940's metal lathe.

Still plugging away. Just putting spacers in between the mounting plates. Then we'll bolt it up to the rest of the robot, and maybe trim some excess metal, and give it a little character.

The fun part will be lining up the two bevel gears. The belt drive system seems to work pretty good.

there's a Video link after the picture.

http://vid295.photobucket.com/albums/mm ... pokck7.mp4

Weapon attached!

http://vid295.photobucket.com/albums/mm ... avt2gt.mp4

Getting close to the deadline. We're set to compete on the 10th of Dec (Saturday) at the Artisans Asylum in Somerville Ma.

The fun part will be lining up the two bevel gears. The belt drive system seems to work pretty good.

there's a Video link after the picture.

http://vid295.photobucket.com/albums/mm ... pokck7.mp4

Weapon attached!

http://vid295.photobucket.com/albums/mm ... avt2gt.mp4

Getting close to the deadline. We're set to compete on the 10th of Dec (Saturday) at the Artisans Asylum in Somerville Ma.

-

Bronurstomp

- Posts: 319

- Joined: 30 Oct 2008, 05:21

- Location: New England USA

Re: Craftsman 1940's metal lathe.

It's actually progressed a lot. I cut three 1/2" spacers, drilled, tapped and countersunk top and bottom, plus 8 more screws holding the spinner subsystem to the robot.

Holy cow am I thankful for torque limiting power screw driver. Only twisted one screw head off so far lol. Was simple to get the broken screw out so no biggie.

I need to weigh this thing soon. It can;t go over 12 lbs, but it should be ok.

Actually I can go figure it out pretty quick...

Gotta love edit...

If I figure correctly, I'll put my shoes back on later, it should be right around 10 lbs as i2. I want it to be as close to 12 as I can get it for the added traction.

Hmm, I wonder what the guy at the post office would say if I asked him to weight it for me.

I'll put it in the car tomorrow and take it to work lol.

ugh, ok Hammer, pics...

http://i295.photobucket.com/albums/mm15 ... 1ynan0.jpg

Holy cow am I thankful for torque limiting power screw driver. Only twisted one screw head off so far lol. Was simple to get the broken screw out so no biggie.

I need to weigh this thing soon. It can;t go over 12 lbs, but it should be ok.

Actually I can go figure it out pretty quick...

Gotta love edit...

If I figure correctly, I'll put my shoes back on later, it should be right around 10 lbs as i2. I want it to be as close to 12 as I can get it for the added traction.

Hmm, I wonder what the guy at the post office would say if I asked him to weight it for me.

I'll put it in the car tomorrow and take it to work lol.

ugh, ok Hammer, pics...

http://i295.photobucket.com/albums/mm15 ... 1ynan0.jpg

Re: Craftsman 1940's metal lathe.

so is the blade going to be at floor level? it looked like it was in the vid - or is the bot upside down there?

Helmut

-

Bronurstomp

- Posts: 319

- Joined: 30 Oct 2008, 05:21

- Location: New England USA

Re: Craftsman 1940's metal lathe.

Yep you're right the blade is at floor level. I'm hoping to get at the other guy's wheels.

Well, as it turned out, I weight it Friday with the postage scale at work and it was 13 pounds! Holy crap and I was hoping to add some armor and steel bits to the corners for added destruction. Now I have to get it home and cut 1 full pound of aluminum off somewhere.

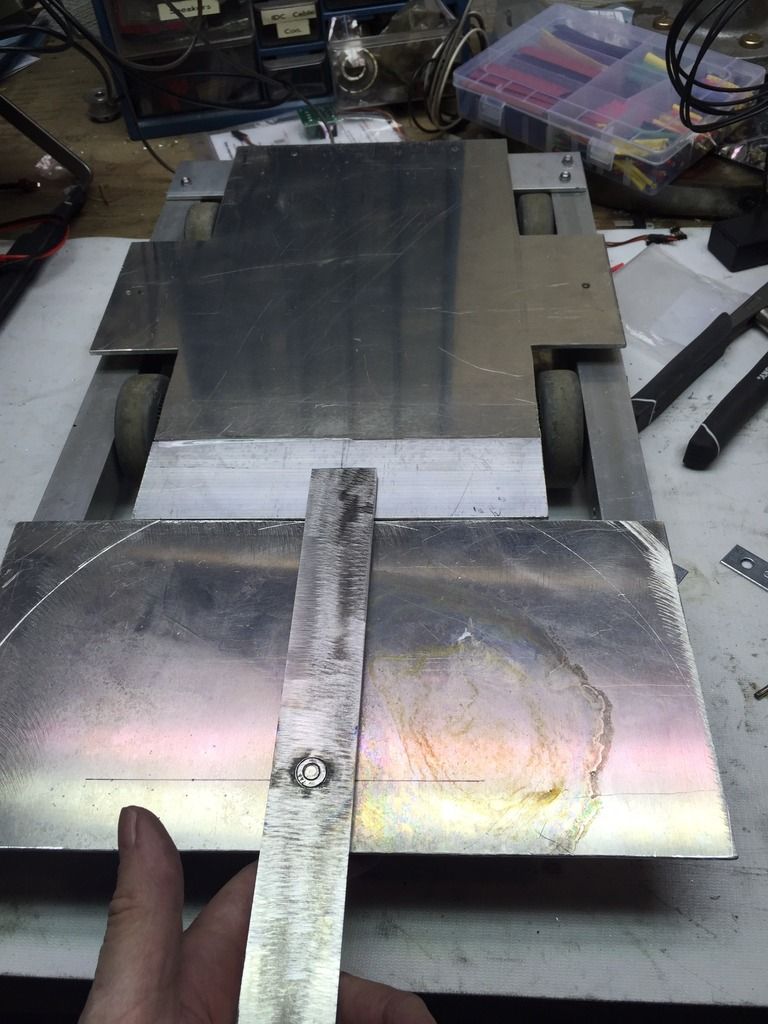

Here is what I was able to remove...

http://i295.photobucket.com/albums/mm15 ... xsqsur.jpg

And so it now likes like this:

http://i295.photobucket.com/albums/mm15 ... xgssxk.jpg

I arranged the piece on top of a blank 12x12" plate, which should weight about 1.5 pounds. Since I didn't have an accurate scale at home, I kept cutting until I got to cover 2/3s of the plate at shown. Add a little for grinding edges down and then drilled a couple 1/2" holes just for giggles... and hoped for the best.

Well, as it turned out, I weight it Friday with the postage scale at work and it was 13 pounds! Holy crap and I was hoping to add some armor and steel bits to the corners for added destruction. Now I have to get it home and cut 1 full pound of aluminum off somewhere.

Here is what I was able to remove...

http://i295.photobucket.com/albums/mm15 ... xsqsur.jpg

And so it now likes like this:

http://i295.photobucket.com/albums/mm15 ... xgssxk.jpg

I arranged the piece on top of a blank 12x12" plate, which should weight about 1.5 pounds. Since I didn't have an accurate scale at home, I kept cutting until I got to cover 2/3s of the plate at shown. Add a little for grinding edges down and then drilled a couple 1/2" holes just for giggles... and hoped for the best.

-

Bronurstomp

- Posts: 319

- Joined: 30 Oct 2008, 05:21

- Location: New England USA

Re: Craftsman 1940's metal lathe.

Yay ! I managed to cut just enough off so it weighed in at 11.85 pounds. Whew!

http://vid295.photobucket.com/albums/mm ... nvgotu.mp4

The event itself was mostly 1 and 3 lb bots. There were probably 8 or 10 in all. The other 12 poound robot didn't show up. Never heard why.

We learned a few things though. I ran Bron2Stomp around the arena for a while before the others showed up. Banging into a wall head on real hard would jam the weapon. No big deal , just need a spacer between the two assemblies to fix that. Also after crashing into the walls a few times to test the ruggedness, we found the alignment would move so it would loose traction. Another easy fix by readjusting after a fight, and re tightening everything.

All in all it was a fun day. Blackhawk, you would have loved the makers space at Artist's Asylum.

At the end, one of the guys let me fight his 6 pound class and I clobbered it badly. He was a real good sport about it too, and we entertained the crowd. I think there were about 25-30 peaple showed up to watch. Kinda neat.

Putting up some vids of the light weights.

My son did the video of the fight where I was driving. Still haven't gotten it from him yet.

Cheers!

Next project coming up soon. Home grown Wind Turbine.

Bron

http://vid295.photobucket.com/albums/mm ... nvgotu.mp4

The event itself was mostly 1 and 3 lb bots. There were probably 8 or 10 in all. The other 12 poound robot didn't show up. Never heard why.

We learned a few things though. I ran Bron2Stomp around the arena for a while before the others showed up. Banging into a wall head on real hard would jam the weapon. No big deal , just need a spacer between the two assemblies to fix that. Also after crashing into the walls a few times to test the ruggedness, we found the alignment would move so it would loose traction. Another easy fix by readjusting after a fight, and re tightening everything.

All in all it was a fun day. Blackhawk, you would have loved the makers space at Artist's Asylum.

At the end, one of the guys let me fight his 6 pound class and I clobbered it badly. He was a real good sport about it too, and we entertained the crowd. I think there were about 25-30 peaple showed up to watch. Kinda neat.

Putting up some vids of the light weights.

My son did the video of the fight where I was driving. Still haven't gotten it from him yet.

Cheers!

Next project coming up soon. Home grown Wind Turbine.

Bron